Table of Contents

Reducing Defects with Data: 5 Smart Quality Control Methods for Busy Plant Managers

In the world of modern manufacturing, even the tiniest slip-up, say, a 1% defect rate, can snowball into missed deadlines, mounting costs, and unhappy customers. If you’re a plant manager managing lean teams, tight schedules, and rising customer expectations, the pressure to get it right the first time has never been greater.

But here’s the good news: data can help.

This guide walks you through five practical, data-powered quality control methods designed to cut defects, boost efficiency, and give you the kind of oversight that turns chaos into control. Whether your operation is just starting to digitize or well on its way, these strategies are field-tested, scalable, and adaptable. We’ve included actionable insights, quick wins, and real-world examples to help you make smart moves fast.

Why Quality Control Needs More Than a Checklist

Let’s face it, old-school quality checks (manual inspections, random audits, after-the-fact analysis) just don’t cut it anymore. They’re slow, inconsistent, and reactive. By the time a problem shows up on your radar, it’s often already a costly issue.

With data-driven quality management, you’re not just spotting defects — you’re preventing them. Here’s how it changes the game:

- Spot problems in real time, not after the fact

- Use predictive models to avoid issues before they happen

- Visualize trends that help your team take smart action

- Drill down quickly to the root cause

- Ensure traceability and standardization at scale

- Empower team members to act on insights, not gut feelings

Companies making this shift are seeing defect rates fall, and productivity, compliance, and customer satisfaction rise.

“It’s not just about fewer defects. It’s about creating a culture where problems are visible and solvable — before they hit the customer.”

1. Predictive Analytics: Stop Defects Before They Happen

Think of predictive quality analytics as your factory’s early warning system. By analyzing historical data and real-time patterns, it can forecast when things might go sideways and give you time to act.

What it looks like:

- Pull data from machines, sensors, and past inspections

- Feed it into machine learning models that know what to look for

- Get alerts before small issues become major problems

- Optimize maintenance schedules based on predicted wear and drift

Example? Say your injection molding machine tends to warp parts when the temperature creeps too high. A predictive system can flag that trend before it costs you a batch.

✅Quick Tip: Start by plugging predictive analytics into your existing SPC or QMS platforms. Even a small pilot can pay off in months.

🟢 Real-world win: One mid-sized plastics company slashed scrap by 28% just by tracking mold temps and cycle times.

📊Advanced play: Add AI-driven anomaly detection to catch complex, multi-variable deviations that traditional SPC misses.

2. Real-Time Vision Systems: Seeing Defects as They Happen

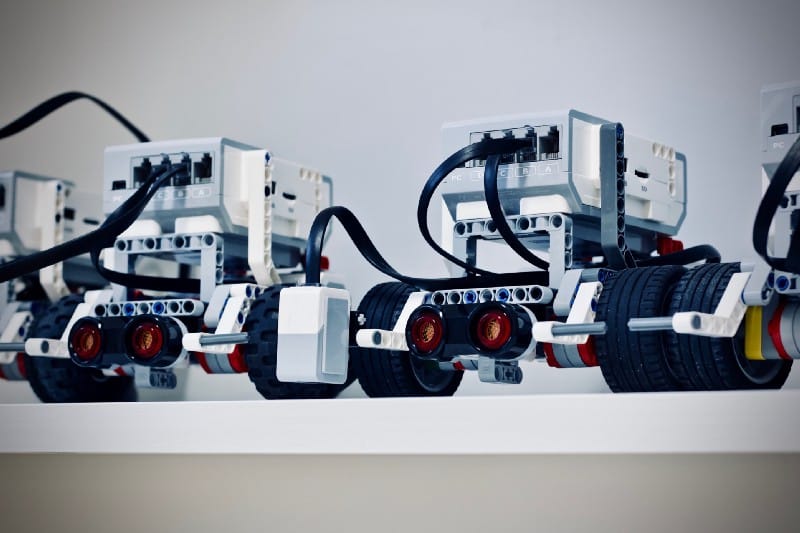

When you want to detect defects as they happen — and at scale — nothing beats real-time, AI-powered computer vision systems. These setups use smart cameras, edge computing, and deep learning models to inspect parts faster and more accurately than any human could.

Capabilities include:

- Scanning for scratches, misalignments, or structural defects

- Measuring components down to the micron level

- Running inspections on high-speed production lines

- Flagging anomalies in real-time based on learned defect patterns

Use Case: In electronics, real-time vision systems monitor soldering temperatures, alignments, and surface defects to ensure every product passes muster before it reaches final inspection.

💡 Tip: Invest in high-quality labeled training data. A well-annotated dataset is critical to training models that generalize well across shifts and product variants.

📈 ROI Insight: Most machine vision systems deliver a payback within 6–12 months, thanks to fewer recalls, faster inspections, and reduced labor costs.

🛠 Stack Suggestion: Combine PLC-connected cameras with edge AI modules and cloud-based dashboards to create a seamless quality intelligence layer.

3. Root Cause Analysis with Visual Intelligence

Even with the best real-time detection, some defects will sneak through. Data-powered root cause analysis (RCA) helps you zero in on why something went wrong fast.

Visualization tools that help:

- Pareto charts: Highlight the most common and costly defects

- Heat maps: Pinpoint geographic or production line trouble spots

- Control charts: Catch drifts and process deviations

- Scatter plots: Discover hidden correlations

- Histograms and box plots: Compare batches, lines, or shifts

📊 Example: A slow rise in cavity pressure? That might indicate tool wear — an early warning before it becomes a downtime issue.

✨Pro Move: Use AI-assisted anomaly detection to discover root causes from multidimensional sensor and production data your team might overlook.

🔍 Next Step: Link RCA tools to your MES or QMS so findings automatically update documentation and corrective actions.

4. Co-Pilot for Quality: Your AI-Powered Assistant on the Floor

Data is only powerful when it’s actionable. Instead of passive dashboards, today’s leading plants are deploying AI-powered co-pilots — virtual assistants that talk to managers, analyze live production data, and make intelligent recommendations.

Your co-pilot can:

- Interpret production metrics in real-time

- Alert you to deviations in yield, scrap rate, or cycle time

- Recommend preventive actions based on similar past patterns

- Summarize plant KPIs in plain language

- Assist in decision-making with cost-impact simulations

Imagine asking your co-pilot: “Why is scrap higher on Line 2 today?” and getting a clear, data-backed answer with recommended actions.

🧠 Tools to consider: Custom LLM-based assistants fine-tuned on your plant’s production history, linked to SCADA systems and quality data pipelines.

🗣️ What sets it apart: Co-pilots bring natural language interaction to complex systems, making insights accessible to everyone from shift leads to execs.

This is the future of manufacturing oversight: smart, conversational, and context-aware.

5. Human-AI Collaboration: The Winning Formula

While AI and automation handle the heavy lifting, human expertise remains irreplaceable. The highest-performing plants pair intelligent systems with empowered operators who can guide, adapt, and improve those systems.

What this looks like in action:

- Operators review flagged anomalies and provide feedback to improve models

- Quality engineers validate AI recommendations and fine-tune rules

- Line supervisors contribute to retraining data with annotated examples

- Cross-functional teams create closed-loop improvement cycles

🤝 It’s not about AI vs. Humans — it’s AI + Humans.

Think of it like reinforcement learning in the wild: humans teach, AI adapts, and the system gets smarter over time.

💡 Best practice: Build training programs around digital literacy, quality analytics, and computer vision basics so your team can work hand-in-hand with intelligent tools.

📚 Pro Development Tip: Use job shadowing and train-the-trainer programs to scale digital skill adoption.

Build Your Data-Driven Quality Control Stack with Us

At Biz-Tech Analytics, we help manufacturers like you:

- Deploy predictive analytics to forecast quality issues before they happen

- Integrate computer vision systems for real-time defect detection

- Build AI-powered co-pilots that talk to plant managers and recommend next steps

- Label and annotate training data to fuel smarter machine learning models

- Enable human-in-the-loop feedback to continuously improve AI accuracy

- Design custom RCA dashboards that reduce time-to-insight and standardize troubleshooting

We’ve partnered with automotive suppliers, electronics manufacturers, and FMCG plants to cut scrap, increase yield, and meet compliance with confidence.

Whether you’re just starting your digital transformation or scaling your existing systems, our custom-built solutions are ready to power your defect-free future.

👋 Let’s Build Smarter, Safer, and More Profitable Operations — Together

Ready to reduce defects, simplify inspections, and boost your plant’s performance?

📞 Book a free consultation to explore how we can tailor these tools to your production line.