Table of Contents

How AI Visual Inspection Systems Are Revolutionizing Quality Control in Manufacturing

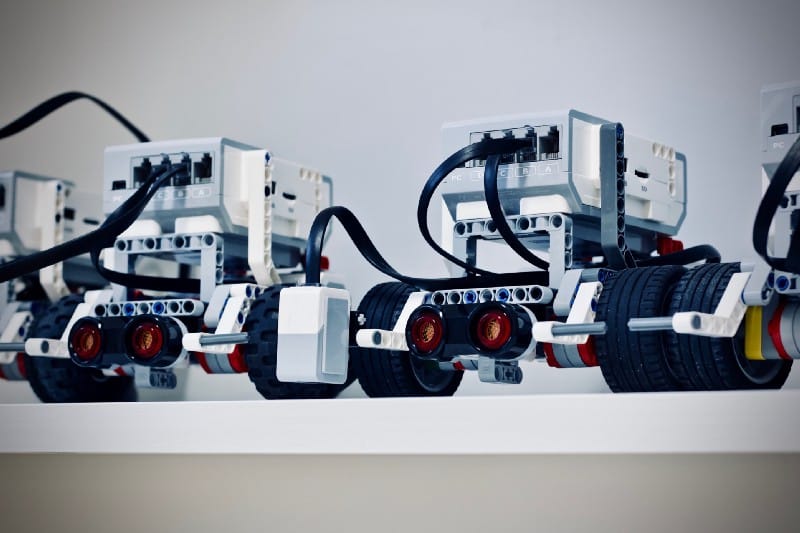

We’re living in the era of Industry 4.0, where artificial intelligence isn’t just a trendy term — it’s a game-changer. One of the clearest examples? AI-powered visual inspection systems. These technologies are redefining how quality control operates on the manufacturing floor, enhancing precision, accelerating processes, and reducing costs in ways that were previously unimaginable.

The Evolution of Quality Control: From Manual to Machine Intelligence

Traditional quality control relied heavily on human inspectors — a process prone to fatigue, inconsistency, and scalability issues. As manufacturing gets faster and more complex, and as customer expectations for perfection continue to rise, these manual methods simply can’t keep up.

That’s where AI steps in. Visual inspection systems driven by machine learning and computer vision can now detect even the smallest product defects with lightning speed and accuracy. They analyze images in real time, often catching issues that would easily escape the human eye.

Key Benefits of AI Visual Inspection in Manufacturing

1. Enhanced Defect Detection Accuracy:

AI systems have pushed defect detection rates up to 96%, sometimes even higher. In electronics manufacturing, for example, they’ve reached an astounding 99.97% accuracy in spotting solder joint flaws. That kind of precision is a game-changer.

2. Increased Inspection Speed and Throughput:

AI doesn’t get tired. These systems can inspect thousands of parts per minute, making 100% inspection a reality without slowing down the production line. That means more output, fewer mistakes.

3. Cost Reduction:

By catching defects early, AI helps reduce waste and the costs tied to rework. Manufacturers have reported to significant reduction in total quality control costs within several years of implementing AI systems.

4. Consistent and Objective Assessments:

Unlike human inspectors, AI systems provide consistent evaluations, eliminating variability due to fatigue or subjective judgment. This consistency ensures uniform product quality and enhances customer satisfaction.

5. Comprehensive Data Collection and Analysis:

These systems don’t just find problems — they gather a ton of data. That info can be used to trace root causes, improve processes, and prevent issues before they even happen.

Real-World Applications Across Industries

Automotive Industry

BMW employs AI to inspect welds on car bodies, detecting imperfections that ensure each weld meets stringent safety standards. Similarly, Ford uses AI-powered visual inspection systems to identify surface defects on vehicle components, enhancing overall product quality.

Electronics Manufacturing

Foxconn, a leading electronics manufacturer, integrated AI visual inspection systems to identify defects in electronic components, resulting in a one-third reduction in operating costs for appearance defects inspection projects.

Pharmaceutical Production

AI visual inspection systems in pharmaceutical manufacturing inspect hundreds of medications per minute, detecting particles, cracks, and fill-level inconsistencies. Facilities utilizing AI inspection technology experienced 64% fewer quality-related recalls compared to those using conventional methods.

Food and Beverage Industry

Food producers implementing AI inspection technology reported an average 22% reduction in customer complaints related to product quality or contamination, thanks to the technology’s ability to detect foreign objects and verify packaging integrity.

Challenges and Considerations

While the benefits are substantial, implementing AI visual inspection systems comes with challenges:

- Initial Investment: High upfront costs for equipment and system integration can be a barrier.

- Technical Expertise: Developing and maintaining AI systems requires specialized skills in machine learning and computer vision.

- Data Requirements: AI systems need large datasets for training to achieve high accuracy, which may not be readily available for all manufacturers.

- Change Management: Transitioning from manual to automated systems necessitates changes in workflows and employee roles.

The Future of AI in Quality Control

The integration of AI in quality control is poised to become standard practice in manufacturing. Advancements in deep learning and computer vision will further enhance defect detection capabilities. Moreover, the combination of AI with other technologies like the Internet of Things (IoT) and big data analytics will enable predictive quality control, allowing manufacturers to anticipate and prevent defects before they occur.

Ready to Elevate Your Quality Control?

At Biz-Tech Analytics, we help manufacturers implement AI visual inspection solutions that drive real results. Whether you’re looking to cut costs, increase precision, or improve efficiency, our tailored systems are built to meet your goals.

Let’s talk — and take your quality control into the future.