Table of Contents

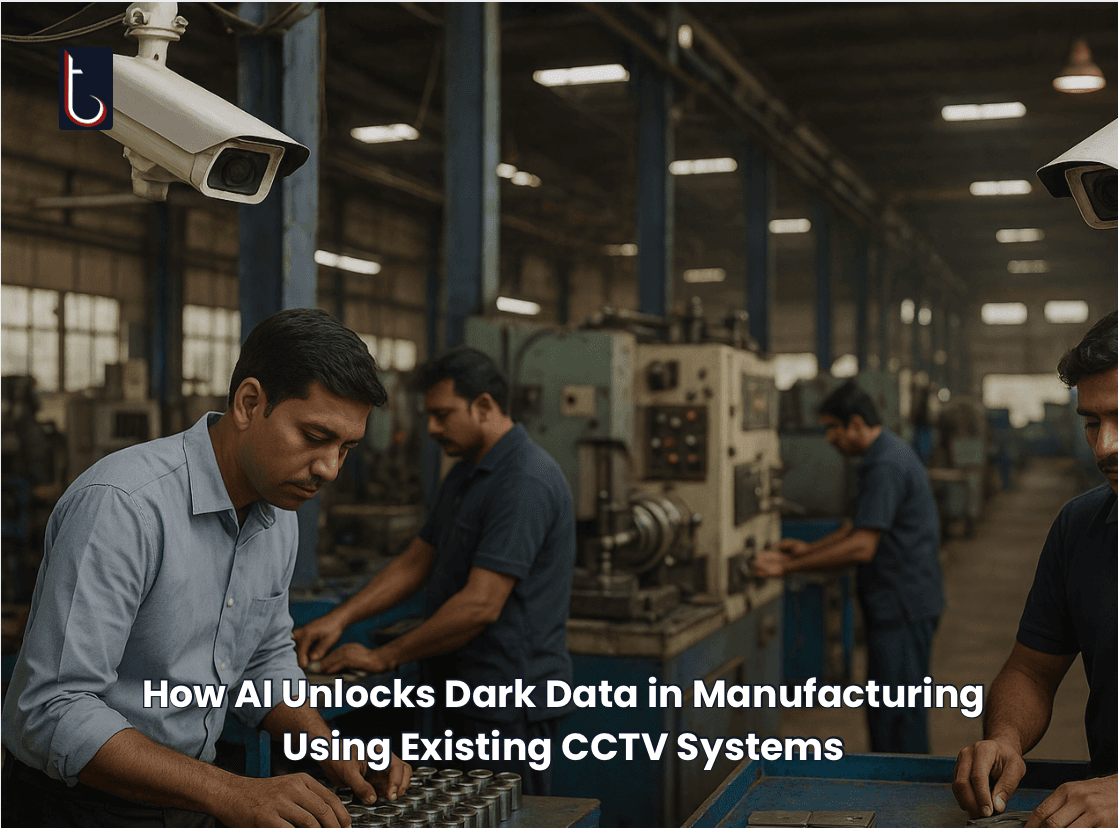

How AI Unlocks Dark Data in Manufacturing Using Existing CCTV Systems

How AI Unlocks Dark Data in Manufacturing Using Existing CCTV Systems

Manufacturing plants capture huge amounts of data every day. Much of it is logged, archived, or simply forgotten. That unused data is called dark data: information collected during normal operations that is not used for analytics, decision making, or process improvement. In modern factories the largest single source of this dark data is video from CCTV systems. When paired with AI, that always-on visual record becomes one of the richest and most actionable data sources on the shop floor.

What is dark data and why it matters for manufacturers

Gartner and other industry sources define dark data as the data organizations collect, process, and store during regular activities but do not analyze or use. In manufacturing this shows up as old logs, sensor telemetry nobody queries, unstructured maintenance notes, and long archives of CCTV footage that are only reviewed after an incident. Dark data represents both a risk and an opportunity. Unused data can create storage, compliance, and security liabilities. At the same time it contains hidden signals that can improve throughput, quality, and safety if made visible.

Why CCTV is often the biggest pool of dark data

Cameras are everywhere in plants. They record continuously and capture operator activity, material flow, machine behavior, and environmental context. Unlike structured sensors, video is rich but unstructured and therefore labor intensive to review. As a result, video archives frequently sit idle. Multiple industry analyses point out that video represents the most underused operational data stream in many facilities and that applying AI to video unlocks insights that were previously impossible to extract at scale.

What AI does to video: turning visual noise into structured signals

Computer vision models process images and video to perform tasks such as object detection, human pose estimation, action recognition, and multi-object tracking. Applied to factory CCTV, these models convert continuous visual footage into timestamped events and metrics. Examples of machine outputs include counts of parts handled, durations of operator tasks, detection of unusual motion patterns, and identification of noncompliance with standard operating procedures. These structured outputs make the footage queryable and connectable to existing systems like MES or ERP.

High-impact use cases of AI in Manufacturing that unlock dark data

Below are practical areas where AI applied to CCTV turns previously dark data into measurable business value.

1. Productivity and cycle time analytics

AI extracts true cycle times, micro-stoppages, and idle times by watching the actual task flow. This surfaces hidden bottlenecks that traditional KPIs miss, enabling targeted improvements to line balancing and staffing.

2. Quality control and SOP adherance

Beyond final inspection, vision models can detect early indicators of likely defects such as wrong part orientation, operator handling issues, or subtle assembly deviations. This supports earlier intervention and fewer downstream reworks.

3. Safety and near-miss detection

AI can detect unsafe postures, entry into hazardous zones, slip or fall events, and near misses. It also tracks missing safety equipment like helmets, gloves, shoes etc. Capturing these near misses helps prevent future incidents rather than only reacting after an accident.

4. Material movement and inventory visibility

Cameras combined with tracking algorithms provide continuous visibility of pallets, parts, and forklifts without the need for full RFID instrumentation. This reduces misplaced inventory and speeds up reconciliation.

5. Predictive maintenance signals from video

Visual cues such as abnormal vibrations, smoke, fluid leaks, or belt misalignment can be detected by vision models and correlated with maintenance records to predict failures earlier. This provides a complementary data stream to sensor-based maintenance systems.

Realistic outcomes and what the evidence says

Vendor case studies and industry reports consistently report improvements in safety, quality, and uptime after implementing video AI. Common, conservatively stated outcomes include reductions in incident rates, faster root cause analysis, and measurable decreases in defect escapes. Note that results vary by plant, process, and the maturity of deployment. Academic and industry analyses also warn that technical integration and data governance are key to realizing benefits.

Practical considerations and pitfalls to avoid

- Data quality matters – Poorly positioned or low resolution cameras reduce model performance. Fix camera placement and lighting before model training.

- Avoid scope creep in pilots – Keep pilots focused on measurable outcomes. Broader ambitions can delay value and cause POC fatigue.

- Plan for integration early – Teams frequently treat video AI as separate from MES or ERP. Early integration planning avoids rework.

- Address privacy and compliance – Masking, on-device inference, and policy controls are necessary for worker privacy and regulatory compliance.

- Measure business metrics not model metrics only – Accuracy and F1 are important, but the business impact is what justifies scaling. Tie model outputs to throughput, scrap, or safety KPIs.

Quick checklist for plant managers (actionable next steps)

- Run a camera coverage audit and identify 3 cameras that capture high-value activities.

- Pick a single, measurable use case for a pilot (for example, pre-defect detection at the final inspection gate).

- Allocate 2 to 4 weeks of labelled footage for initial model training.

- Define 3 KPIs to track during the pilot: e.g., worker productivity, percent of idle time, percent of defects detected, etc.

- Find a computer vision solutions expert vendor like Biz-Tech Analytics for training, deployment and integration.

Closing thoughts

Dark data in manufacturing is not a hypothetical opportunity. Video from existing CCTV systems is an untapped asset that AI can convert into continuous operational intelligence. When approached pragmatically with pilots, careful integration, and a focus on business KPIs, video AI moves CCTV from passive surveillance to an active source of insights that improve throughput, quality, and safety. The factories that systematically mine their dark data will gain a durable advantage in operational visibility and responsiveness.

Frequently Asked Questions (FAQs)

1. What is dark data in manufacturing?

Dark data refers to information factories collect during daily operations but never analyze. This includes unused sensor readings, old reports, maintenance notes, and especially hours of CCTV footage that remain unreviewed.

2. Why is CCTV footage considered dark data?

CCTV captures everything that happens on the shop floor but humans cannot manually review it. Since the footage is rarely analyzed, it becomes one of the largest sources of untapped operational insight.

3. How can AI unlock hidden insights from video?

AI models detect objects, worker actions, movement patterns, cycle times, anomalies, and safety events. This converts unstructured video into structured data that factories can use to improve productivity and quality.

4. How much data is dark data?

Industry estimates often state that more than half of all data collected across enterprises remains dark. In manufacturing it can be even higher because most visual and process data is not structured or integrated into analytics systems.

5. What are the benefits of using AI to analyze dark data?

Manufacturers gain better visibility into bottlenecks, defects, unsafe events, and process variations. This improves throughput, reduces rework, and supports stronger audit readiness.

6. Is video based AI difficult to implement?

Most factories already have camera infrastructure. AI deployment usually involves selecting the right camera views, training models on sample footage, and integrating output into existing digital systems.

7. Can AI work with low quality or older CCTV cameras?

In many cases yes. Standard resolution cameras are suitable for activity understanding and safety analytics. Higher resolution may be needed for fine defect detection.

8. Which Indian companies offer dark data analytics services?

Several Indian firms provide analytics and AI solutions that help enterprises use unstructured or unused data. Companies active in this space include Biz-Tech Analytics, Fractal Analytics, Tredence and LatentView which also focuses on unlocking dark data from CCTV streams for operational visibility in manufacturing.

9. Where can I find case studies on dark data management in retail?

Case studies are available from digital transformation consultancies, AI research groups, and analytics providers. Many retail focused examples can be found in reports by consulting firms and AI vendors. Biz-Tech Analytics also shares insights on how retailers can use video and unstructured data to improve store operations.

10. What are common use cases of AI for dark data in manufacturing?

Typical use cases include worker productivity and idle time tracking, defect detection, cycle time analysis, micro stoppage detection, process deviation alerts, forklift and material tracking, and identification of unsafe events.