AI & ML in Manufacturing

By Ananya Avasthi & Rohan Khanna

Artificial Intelligence has taken over several industries and it’s not surprising to see AI and machine learning slowly being implemented in modern manufacturing plants to increase efficiencies while reducing costs and risks. There are countless use cases of AI & ML in manufacturing, as well as ways in which it contributes to value creation.

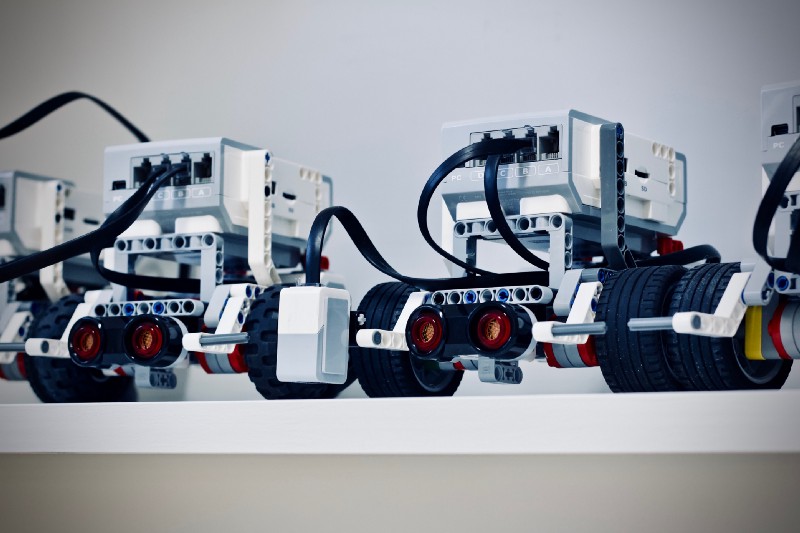

Today, manufacturing has become fiercely competitive with rapidly changing markets, looming and sporadic pandemic waves disintegrating supply chains, escalating crude prices, increased protectionism, increasing labor costs, and shrinking profit margins. Besides, there are scores of complicated moving components which require critical attention to every section of the facility so that the process does not go awry. Amidst such a scenario industry requires a revolutionary turnaround to counter all the ill effects which might determine the future course of the manufacturing industry and also millions of people employed by it. Presently implementing AI/ML in manufacturing is believed to be one of the few palliative measures provoking innovation, automation, modernization thus increasing profitability and productivity. Predictive analytics, robots, predictive maintenance, and automated processes are some use-cases of machine learning in manufacturing that aid in making operations more efficient and safe.

Computer Vision and AI

Computer vision is a branch of computer science and machine learning that focuses on developing digital systems capable of processing, analyzing, and making sense of visual inputs in the same manner that people do. The notion of computer vision is centered on training computers to analyze and comprehend images at the pixel level. Machines use sophisticated software algorithms to retrieve visual input, process it, and interpret the findings. The process includes training models on vast amounts of data ranging from 100K inputs to tens of millions of inputs, depending on the complexity of the model.

Because a computer vision model can analyze thousands of products or processes a minute, it can quickly surpass human capabilities. Today, Computer Vision is used in a variety of use-cases ranging from self-driving cars to cyber-security to manufacturing.

Use Cases of Computer Vision with Manufacturing

Predictive Maintenance

Predictive Maintenance is described as the process of determining when asset management is required by combining machine learning and IoT. Sometimes, due to dysfunctional components production is halted. Any firm that relies on physical components knows that this can result in significant losses. AI/ML solutions can enable producers to extend the life of their equipment and at the same time prevent huge production losses by alerting the firm of an upcoming component failure. For example, an industrial supplier created a software application that collects images from cameras linked to 7000 components in 38 smart plants facilities. This picture collection, when combined with the metadata, identifies the components that are approaching their end of life which are then replaced or refurbished thus preventing multiple component failures.

Product Inspection/Quality Control

The most crucial production operations that should not be overlooked are product inspection and quality control. For instance, pharmaceutical companies struggle to control the quality of each and every capsule that is packaged. This problem has been solved by an English firm that used computer vision to analyze the tablets before they get packaged. At the last stage of the manufacturing process, a computer vision-based inspection system is deployed and if a tablet is found faulty, the system sends a signal to reject it. This technology uses computer vision to determine whether the tablets are of appropriate color, breadth, and length. This system substantially eliminates the risk of substandard medications being transported and maintains the high quality of the product.

Product and Components Assembly

A machine vision system may be used in manufacturing plants to ensure that component and product assembly adheres to strict specifications. A bottling company, for instance, may inspect bottles from every angle to ensure proper packaging. They would look at the label, cap seal, and placement of package bottles, among other things. Product recalls are reduced as a result of these stringent requirements, which also result in an increase in output. This also means that customers are pleased and satisfied with the final product.

Reading Text and Barcodes

Recognizing text and reading barcodes is a cumbersome task on the factory floor, which can be optimized to significantly improve overall production output. Future factories will see the emergence of upgraded computer vision systems and industrial automation to overcome this challenge.

Presently, for instance, manufacturers of printed circuit boards (PCBs) can reduce their operational costs by employing a computer vision solution. Similarly, Optical Character Recognition (OCR) technology is being used in industries to make real-time data in image machines meaningful and readable. In addition to that advanced text recognition technologies such as Optical Mark Recognition (OMR), Intelligent Character Recognition (ICR), Barcode Recognition (OBR), and other image processing technologies are increasingly being implemented by hardware and software vendors to improve the functionality of existing computer vision systems.

Defect Reduction

Most production defects occur in the early stages of the manufacturing process, however, these defects are mostly discovered during the finishing stages. Using machine-learning techniques on existing manufacturing data, coupled with a computer-vision-based solution for visual inspection to classify defective products, can allow manufacturing plants to analyze which production paths cause defects. In turn, manufacturing companies can discover defects earlier in the production process and perform defect handling by either adapting the remainder of the manufacturing process or scrapping the current product at an early stage, thus preventing unnecessary production steps and saving time and resources. This kind of preventative approach to defect handling can significantly improve the overall yield and quality of the manufacturing plant. In addition to discovering and reducing defects, this solution also has the capacity to identify possibilities for as yet unknown improvements in the production process.

Biz-Tech Analytics and Manufacturing

Data collected at manufacturing plants, both historic and current, is mostly unlabelled data and hence mostly unusable as-is. Labeling this wealth of data can truly unlock its potential to help achieve many of the improvements and optimizations listed above.

Biz-Tech Analytics provides human-powered Data Annotation Services to teams working on Artificial Intelligence and Machine Learning problems. Our team of annotators is equipped to provide Text, Image, Audio, and Video Annotations for a plethora of use-cases, especially manufacturing.

Some key factors about our services include:

- Faster delivery using ML assisted labeling

- Customizable - plug and play - quality assurance, security, and data delivery measures & practices.

- Flexible - Annotators can work on your existing annotation platform or we can provide a platform best suited for your needs

- In-house battle-tested data security and quality assurance measures and practices (with an added focus on high-quality consistent labeling)

Our goal is to help revolutionize the companies that we work with by helping them build cutting-edge AI/ML applications that will not only help their businesses flourish but also have innovative & disruptive impacts on their fields. To help achieve this goal, we are also working on providing end-to-end AI/ML solutions to the manufacturing industry. We are creating Industry 4.0 solutions to improve efficiencies while reducing costs and risks for our customers.

Please get in touch to learn more about how Biz-Tech Analytics can bring a data-centric workflow to your AI project.