Table of Contents

AI in Manufacturing: Eliminating Idle Time with Smart Productivity Solutions

Why AI in the Manufacturing Industry

In modern manufacturing, productivity is often measured by output per hour, yet a significant amount of time on the shop floor is lost due to unmonitored idle time. Even small inefficiencies at individual workstations can cascade into missed deadlines, excess costs, and lower equipment utilisation. Traditional methods of supervision – manual observation and reporting – are limited in scale, prone to human error, and lack real-time responsiveness.

Artificial Intelligence (AI) is now changing the equation. With AI-powered workstation productivity tracking, manufacturers can automatically monitor operator activity, distinguish between active and idle time, and generate real-time insights that drive measurable improvements in efficiency.

The Problem: Hidden Idle Time on Production Lines

Every workstation is a micro-unit of production. If operators spend even 5-10% of their shift in idle mode due to distraction, delayed material supply, or poor process allocation, the cumulative effect can translate to hours of lost output daily. Supervisors may not always notice these inefficiencies, especially across multiple production lines or plants.

In many factories, supervisors lack visibility into:

- Worker availability (how much of the shift an operator spends at the workstation).

- Productivity levels (units processed vs. target).

- Idle time vs. active time (whether downtime is due to scheduled breaks or unplanned pauses).

- Quality events (units rejected or passed without proper inspection).

Without clear visibility into who is working, who is idle, and why, manufacturers struggle to enforce accountability and optimise resource allocation.

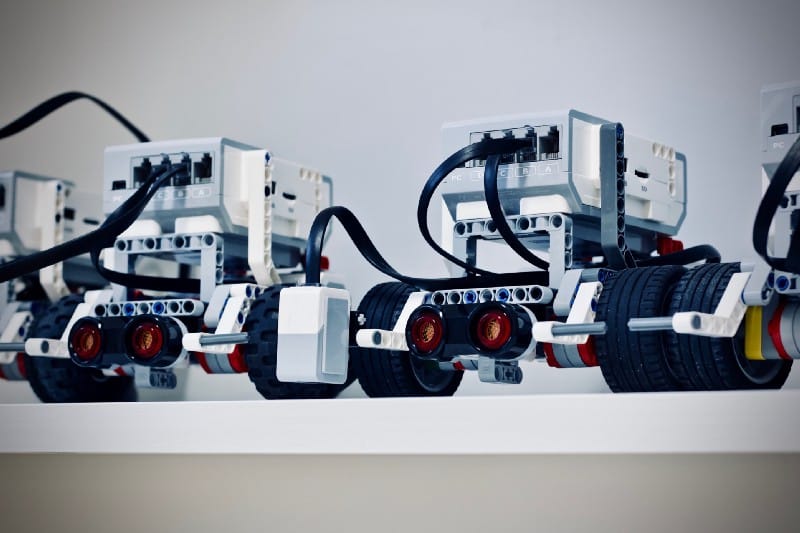

AI in Manufacturing Examples: Human Pose Recognition for Productivity

Advancements in computer vision have made it possible to apply human pose recognition technology to manufacturing environments. Using standard cameras and AI models trained on skeletal pose detection, the system can:

- Identify when an operator is engaged in productive activity (assembly, machine operation, inspection).

- Detect idle states such as sitting, standing still, or disengagement from machinery.

- Differentiate between planned pauses (e.g., machine cycle time, approved breaks) and unplanned idle time.

This is one of the most practical use cases of AI in manufacturing industry operations. It enables continuous, non-intrusive monitoring without requiring manual input from workers or supervisors.

Real-Time AI Use Cases in Manufacturing to Boost Productivity

Our AI-driven productivity dashboard consolidates all workstation data into clear, actionable signals. For example, managers can instantly see:

- Workstation output vs. target to identify which stations are underperforming.

- Idle time thresholds being exceeded, with alerts to supervisors.

- Availability comparisons across workers, highlighting where low engagement is reducing throughput.

- Quality and safety events pinpointing when errors or non-compliance occur.

Instead of reacting after a missed production target, supervisors can proactively intervene, redistributing workloads, addressing supply chain delays, or coaching workers in real time.

Data-Driven Coaching and Utilisation Metrics

Beyond real-time monitoring, AI dashboards build long-term operator performance profiles. Typical metrics include:

- Average active vs. idle time per shift.

- Units processed within target handling time (a measure of efficiency).

- Comparative benchmarks across workers or shifts to identify top performers.

- Break adherence and overruns, highlighting where downtime exceeds allowances.

- Safety compliance rates, aligned with quality outcomes.

This transforms workforce management into a data-driven process. High performers can be recognised and incentivised, while coaching and corrective measures can be targeted at areas of weakness. Over time, this data also informs workforce planning and process redesign.

Business Impact of AI in Manufacturing

Manufacturers adopting AI-powered workstation tracking are reporting:

- According to McKinsey & Company (2022), early adopters of intelligent manufacturing AI reported productivity improvements ranging from 20% to 50%.

- Up to 40% overall productivity gains across production lines, according to an ASSOCHAM-Odisha State Development Council Report

- A Siemens factory observed a whopping 37% increase in OEE

- Better quality control, with precise tracking of rejected or missed-inspection units.

- Improved accountability and morale, as performance is measured transparently and fairly.

The combination of real-time visibility and actionable analytics enables quick wins in the short term while building a foundation for continuous improvement.

Why AI for Manufacturing Now?

Several factors make this the right time for manufacturers to embrace AI idle time monitoring:

- Affordable Hardware: Standard IP cameras and edge devices can support AI vision workloads without massive investments.

- Mature Algorithms: Pose recognition models have reached high accuracy levels even in complex environments.

- Scalability: Cloud-based dashboards allow multi-plant visibility, creating standardised KPIs across geographies.

These trends are fueling a broader shift toward smart manufacturing AI solutions, where factories adopt connected, AI-driven technologies to stay globally competitive.

Other Applications of AI in Manufacturing

While workstation tracking is one of the most impactful, other AI use cases for manufacturing include:

- Automating and monitoring defect detection for quality assurance.

- Monitoring SOP & PPE compliance with instant alerts

- Using facial recognition for attendance, shifts and access management

- Generating space and heat map for factory floor optimisation

These applications show that AI is not limited to workforce monitoring but is transforming the entire production ecosystem.

Conclusion

AI-powered workstation productivity tracking is not about surveillance; it is about enabling transparency, accountability, and efficiency on the factory floor. By eliminating hidden idle time, manufacturers can unlock substantial productivity gains, optimise labour allocation, and stay competitive in an increasingly efficiency-driven market.

The result: fewer hidden inefficiencies, faster decision-making, and significant productivity gains that strengthen the future of AI in the manufacturing industry.

Want to know how you can do the same for your factory? Contact us today!